Next Gen Road King™ Bits

Showing the single result

Looking for the NEXT-GEN Road King™ updated part number? Use this conversion sheet. The tool series provides superior milling machine performance. Its new design elements maximize tool life and make tooth changes

easy and efficient for operators.

Superior Performing Teeth with

• Improved body, washer, and retainer optimize carbide tip use.

• Wear indicators make it easy to evaluate remaining tooth

use life.

• Stronger body, washer, and retainer facilitate service access

to tooth and deliver greater stability.

• Holder protection is increased, providing more uniform cuts

with better rotation and reduced axial play.

• Compatible with all old and new generation 20mm

tool holders. KENNAMETAL INNOVATION GIVES CLIENTS A CHOICE

KENNAMETAL INNOVATION GIVES CLIENTS A CHOICE

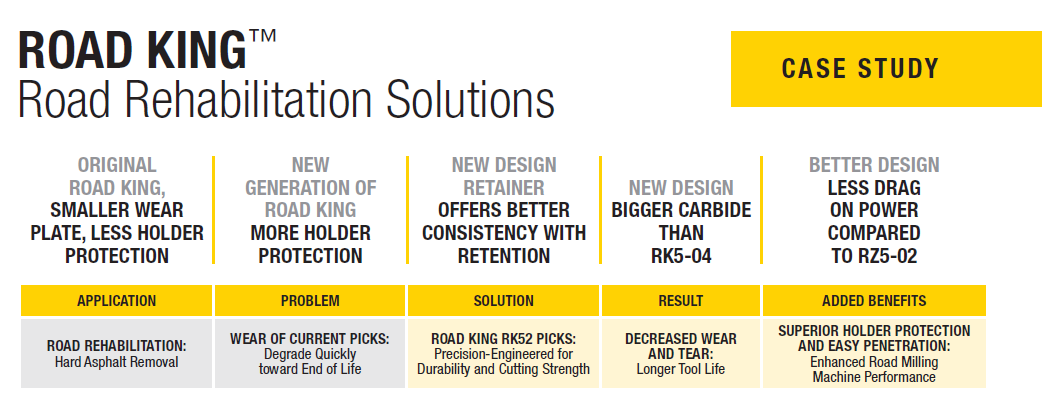

A client operating a high-horsepower, half-lane road milling machine to remove asphalt was interested in comparing existing supplier’s

picks to Kennametal’s Road King series. The client wanted to know how both sets of tools stacked up in terms of lifespan, body wear,

carbide wear, and retainer and washer wear.

Our RK52 road rehabilitation pick is precision-engineered

for durability and cutting strength, combining superior

holder protection and easy penetration to drive

exceptional machine performance.

ROAD TEST CONDITIONS

The client decided on a split-drum comparison, with 100 RK52 tools placed on the right side and the incumbent supplier on left side of the 2.2m milling drum. The drum was of average mid-life condition, and its OEM holders showed significant yet consistent wear across the drum to still leave a nice pattern. The test was conducted over two days in October 2023, with rain and wet surface conditions the entire time. Two inches of hard asphalt road surface were removed over a distance of 30,000 feet, with both sets of tools checked by the milling machine’s operators at the middle and end of each work day.

TOOL PERFORMANCE CONCLUSIONS

GRIND OUT MORE WITH KENNAMETAL ROAD REHABILITATION TOOLS

Want these kind of results? Talk to our experts to learn how our Road King solutions can help you rule the road.

• Tool Lifespan — Both sets of tools performed similarly and were changed out at the same time towards the end of the second shift,

but four non-Kennametal picks experienced premature breakage.

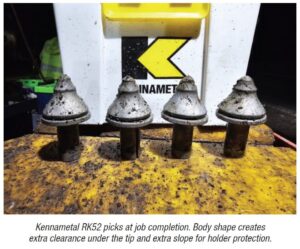

• Body Wear — RK52 tools showed desired hourglass shape indicating extra clearance and holder protection.

• Carbide Wear — As the picks began to work, the RK52 sharpened fi rst and then both styles cut and wore in the expected shape.

All picks were changed before completely losing their cutting point.

The machine operators preferred how the carbide tip in each RK52 pick resisted wear. And based on their experience,

they believed RK52 could last even longer under different conditions!

The information contained in this case study is intended for comparative purposes only and is based upon limited test samples.

The information is no guarantee of actual future results. The information is provided “as is” without warranty of any kind, whether expressed or implied.

GRIND OUT MORE WITH KENNAMETAL ROAD REHABILITATION TOOLS

Want these kind of results? Talk to our experts to learn how our Road King solutions can help you rule the road.